The exterior of the building is cladded with porcelain tiles, Pezc Zoo, Hungary

The product is available upon request

When it comes to tiles for industrial and commercial projects, porcelain stoneware tiles are the go-to materials for any designer or architect. The material seems to tick every box for those who are looking to fulfil the high industrial standards and have creative flexibility and fit within the budget.

Before we get to the technical specifications, let’s talk about

the aesthetics of porcelain stoneware

Quality and durability no longer have to cost you a beautiful design. Gone are the days of boring, all-too-safe white or cream tiles that we see too often in hotel bathrooms.

With an advanced ink-jet printing technology manufacturers can produce porcelain tiles of any design, pattern – be it an imitation of natural stones, terrazzo, or even a photographic image – with remarkable consistency and clarity. This makes porcelain stoneware perfect for large scale projects.

Terrazzo immitation Porcelain floor tiles

The product is available upon request

So what exactly is porcelain and how is it different from ceramic tiles?

Most people use ceramic and porcelain interchangeably, which isn’t too far off.

Essentially, porcelain is a material that belongs to a larger ceramic family.

There are three types of ceramic tiles: floor, wall and porcelain. The difference between the three is in the production process that changes their physical properties and characteristics.

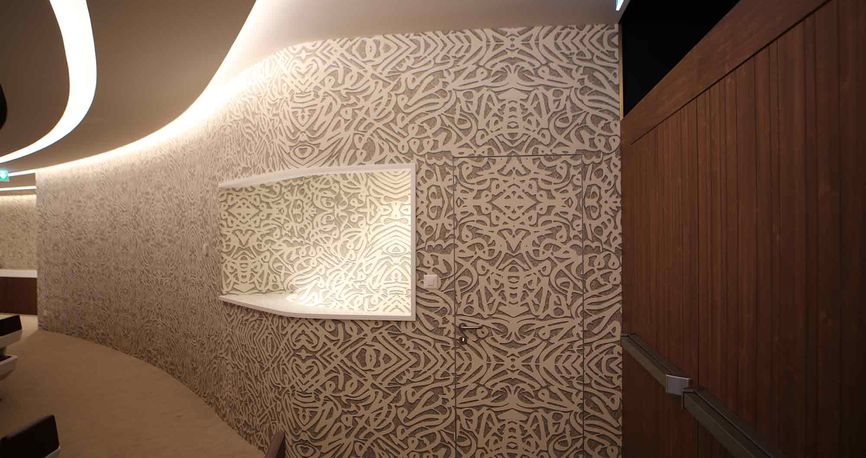

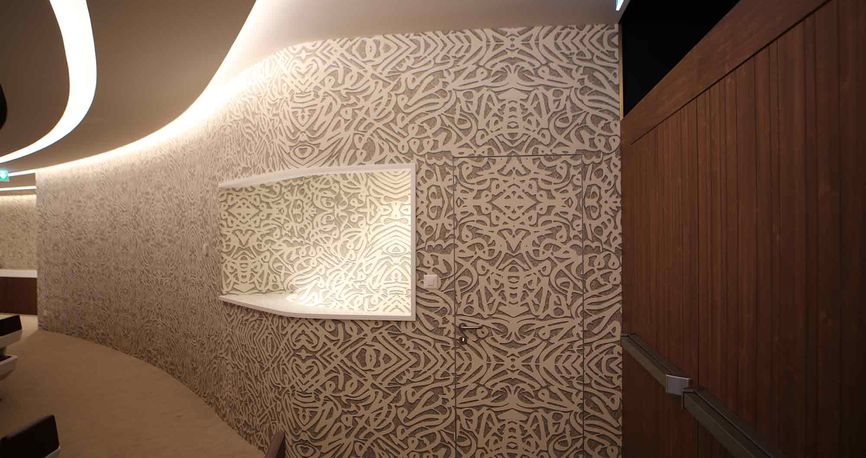

Art Nuovo inspired Porcelain floor and wall tiles

Product samples are available upon request

What is a ceramic tile?

A technical description according to the industry manuals describes ceramic as:

Thin slab made from clays or other inorganic raw materials, generally used as covering for floors and walls, usually shaped by extruding or pressing at room temperature, but may be formed by other processes, then dried and subsequently fires at temperatures sufficient to develop the required properties.

Ceramic tiles have been produced for centuries, and they are either glazed or unglazed, non-combustible and hardly affected by sunlight.

However, resistance to temperature, water and physical damage are defined by the manufacturing process. Most ceramic tiles certainly have aesthetic value and authenticity, however, are not suitable for heavy traffic or outdoor usage.

International airport Hamad, Doha, Qatar

Product samples are available upon request

What’s the advantage of porcelain tiles?

As you may have already guessed, porcelain is the most advanced material in terms of technical performance among other ceramic types.

When it comes to determining the quality and performance of the material, UNI standards in Italy, EN Standards in Europe and ISO standards world-wide define the most important features of ceramic tiles, which we’ll discuss further in details:

Room XIX of the United Nations with custom porcelain wall design

Custom designs are available upon request

Regularity in dimensions, thickness, straightness of corners and flatness

To be classified as top-quality tiles, the material must be perfect in all measurements.

Tiles must have identical dimensions and thickness, must have no hollows or rises, and have their sides set at perfect right angles.

The appearance of the tiles must be uniform, and the definition of grinding on the sides and corners are some of the peculiarities that identify high-end ceramic products.

Water absorbency of porcelain tiles

Water absorbency is defined by a percentage of water impregnating a tile. It is one of the most essential qualities that determine the quality and dependability of the tile.

Porcelain tiles are the least porous of all other ceramic materials. The water absorption rate is determined by the degree of porosity of porcelain tile, and it must be less than 0.5% to be sustainable for outdoor and wet areas.

Ceramic tile’s water absorbency standards according to ISO10545

Slip resistance

Slip resistance test is carried out on a range of surfaces and finishes across porcelain and ceramic tiles.

In European countries, the quality is measured by a German method of European Ramp Test DIN 51130 / 51097. But, the UK has its Pendulum Test BS7976 – the only method recognised by the Health and Safety Executive.

This method is based on a swinging imitation heel, which sweeps over a set area of flooring, and is measured by a pendulum test value (PTV). The UK HSE recommends the following:

High Slip potential 0-24 PTV

Moderate Slip potential 25-35 PTV

Low Slip potential 36 PTV

Most of our products arrive from the EU and are tested according to the DIN 51130 / 51097 method. You can further read here about the European standard measurements for slip resistance.

Resistance to breakage

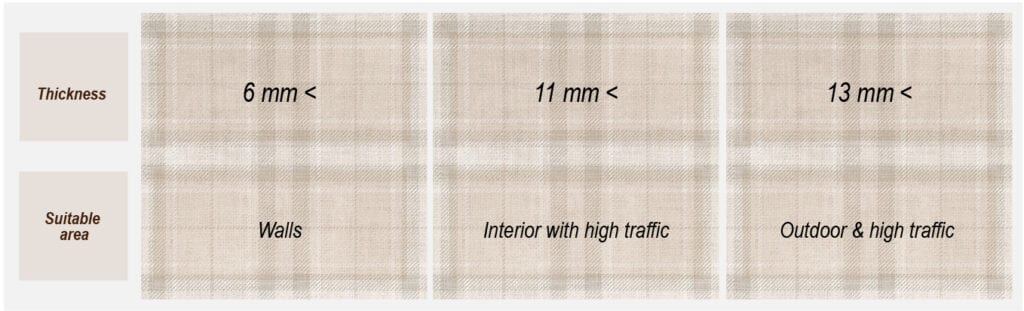

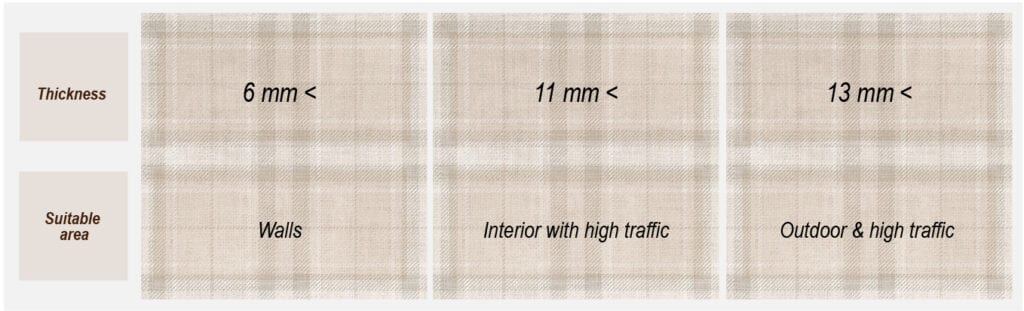

An important distinguishing element to determine ceramic tile’s ability to resist breakage and bending is linked to low-water-absorbency percentage and the thickness of the material.

Porcelain tiles that are appropriate for outdoor and high-traffic areas must be of at least 13 mm.

Our range of standard porcelain tiles come from 12 -20 mm in thickness. And porcelain slabs are produced at 12, 20, 30 mm and above upon request.

Ceramic tile’s thickness and standard application according to ISO10545

Resistance to temperature excursions and frost

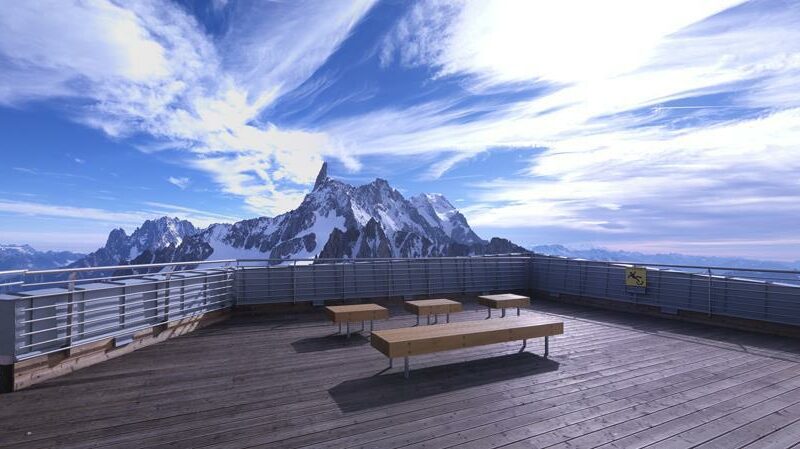

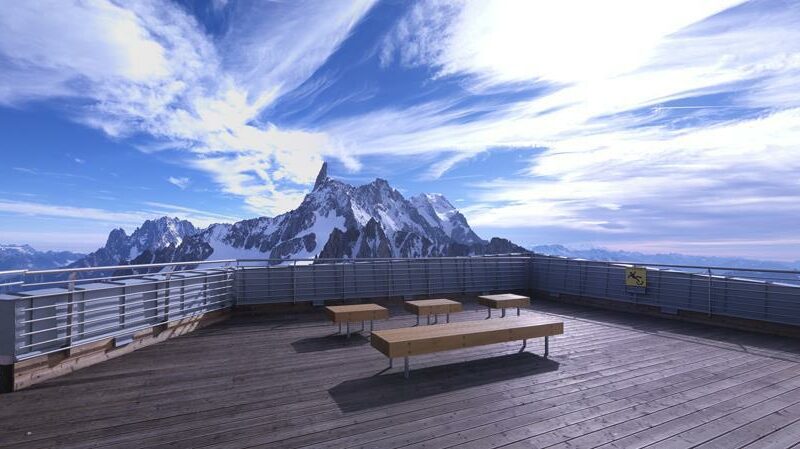

14mm porcelain tiles for terrace in Skyway Monte Bianco ski resort, Courmayeur, Italy

Product is available upon request

The thermo-hygrometric properties of porcelain tiles depend on its high density. As the material has the lowest porosity, therefore, absorbs less water, the risk of cracking under pressure caused by the increase in the volume of water as it freezes is very unlikely.

That’s why the material is the most suitable for outdoor areas, such as patios or near swimming pools, etc.

Lightfastness

Porcelain tiles used for outdoor patio and pathway, Villa Malta, Italy

Product is available upon request

Porcelain tiles often used in outdoor flooring or on the facades of buildings, where the material is exposed to sunlight for prolonged periods. Hence, there is a need to test the material’s physical and chemical property to maintain its original colouring and uniformity.

The standards for this property are set by German DIN 51094 standards.

Our range of porcelain products are resistant to all weather conditions and proved to maintain tile colour unaltered.

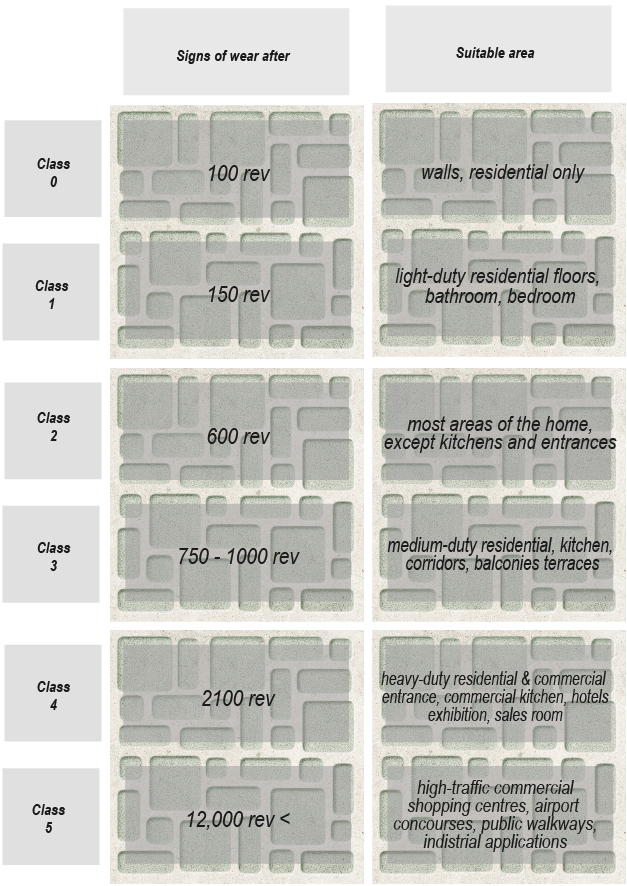

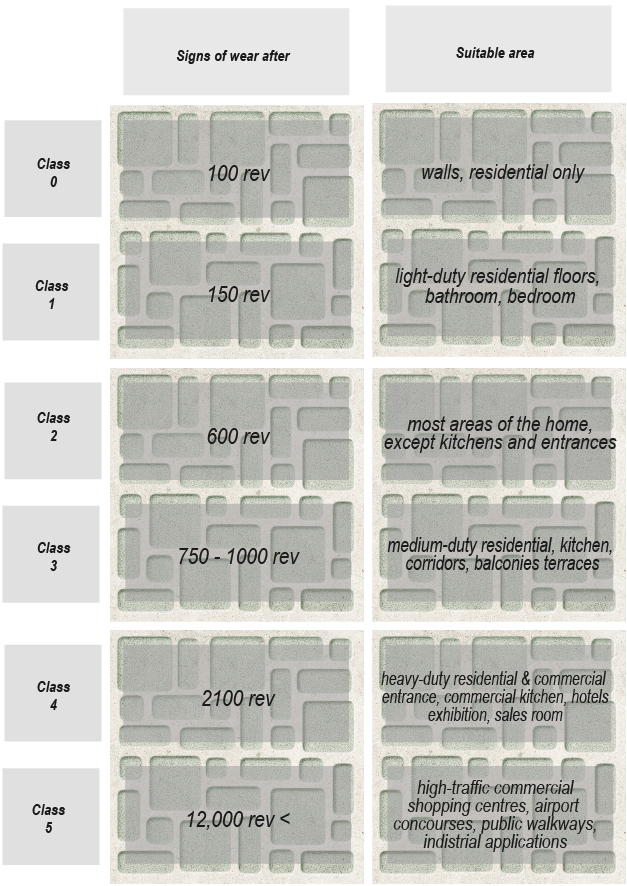

Resistance to abrasion and deep scratches

Ceramic materials must guarantee resistance to scratch and wear caused by footwear and movement of furniture, wheeled trolleys, etc. over time, to maintain the original surface texture and functionality.

Porcelain tiles are distinctively compact and guarantee enduring performance.

The PEI system is a universally recognised method of grading tiles according to surface wear and is tested by various rotating wheels that imitate traffic. The method suggests the following application of porcelain tiles in accordance to their resistance measurements:

PEI system of measuring ceramic tiles resistance to abrasion and scratches

Chemical resistance

Porcelain tiles immitating natural stone finish, suitable for wet areas and resistant to all household cleaning detergents and industrial-grade chemicals

Order porcelain tile sample

The compactness and low porosity of the material’s surface plays an important role in resisting chemical substances contained in domestic and industrial cleaning products, or acid, in some working environments. The compactness of porcelain extends throughout its surface and does not allow penetration of such aggressive substances. This property is achieved by the high firing temperatures reached in ceramic kilns.

Bacteria resistance

Porcelain tiles with distressed wood effect are used for the bathroom flooring, Agriturismo Biologico Sant’Egle, Italy

Product samples are available to order

Bacteria resistance is another great property of porcelain tiles, which makes them suitable for private and public showers, swimming pools and other wet areas. The optimized product was obtained through a new product formula, which acts as a barrier to the bacteria’s growth during a long period, and anti-stain action.

Also, our porcelain tiles are free of any volatile organic compounds (VOC free).

Sustainability

Porcelain tiles are used for the facade of the building, Bosco Verticale, Milan, Italy

Product samples are available upon request

Ceramic or porcelain tiles are manufactured using plentiful natural materials, easily maintained without the need for harsh chemicals and have an expected life span of over 50 years when installed and maintained properly.

Our porcelain tiles consist of 93+% of natural marble, quartz, clay and dolomite with various bonding and colouring agents. The raw materials are sourced locally and manufactured in an environmentally sustainable manner.

If you have any further enquiries about our Porcelain products, we are always happy to help.